President

Tatsuhiko Asakawa

GREETING

Asakawa has always invested a great deal of effort into developing new products and improving our technology since the company was established as a manufacturer of fasteners in 1946.

Asakawa developed deformation processing technology, centered on cold forging processing and established a comprehensive production system that included heat treatment and coating, very early on.

Asakawa responds to the requirements of customers and supplies fasteners and other parts essential for engines and underbody of vehicles and industrial equipment, which require high quality and high performance. in this way, Asakawa contributes to industry development as a leading manufacturer.

Aasakawa is expanding from being a manufacturer of fasteners to a comprehensive metal parts manufacturer to meet customer requirements which are becoming increasingly diverse and global.

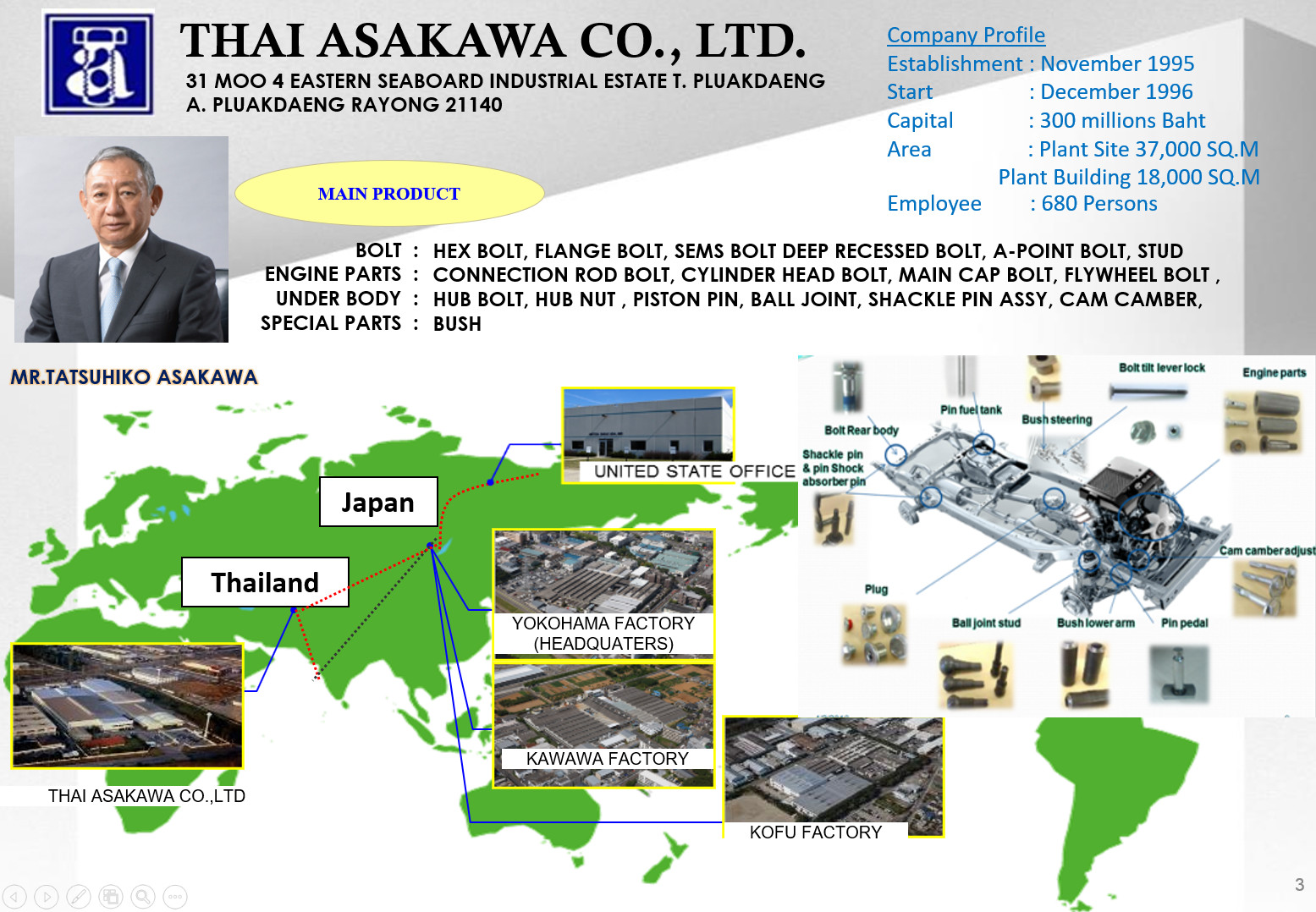

Company Profile

OFFICE : 31 MOO 4 EASTERN SEABOARD INDUSTRIAL ESTATE T. PLUAKDAENG A. PLUAKDAENG RAYONG 21140

PHONE : 038-954523-6

FAX : 038-954527, 954754

E-MAIL ADDRESS : marketing@asakawa.co.th

CAPITAL : 300 MILLIONS BAHT

ESTABLISHMENT : NOVEMBER 1995

START : DECEMBER 1996

QS9000 CERTIFIED : FEBRUARY 2002

ISO14001 CERTIFIED : AUGUST 2003

ISO/TS16949 CERTIFIED : JUNE 2005

AREA : PLANT SITE 37,000 SQ.M. PLANT BUILDING 35,000 SQ.M.

EMPLOYEE : 680 PERSONS (ACTUAL 2016)

About us

We do our utmost to provide reliable products for customer satisfaction, pursuing our policy "Quality First“

A great number of special components, engine parts and underbody parts, all of which require the highest quality and accuracy among vehicle parts.

Certificate

IATF 16949:2016

ISO 14001:2015

ISO 9001:2015

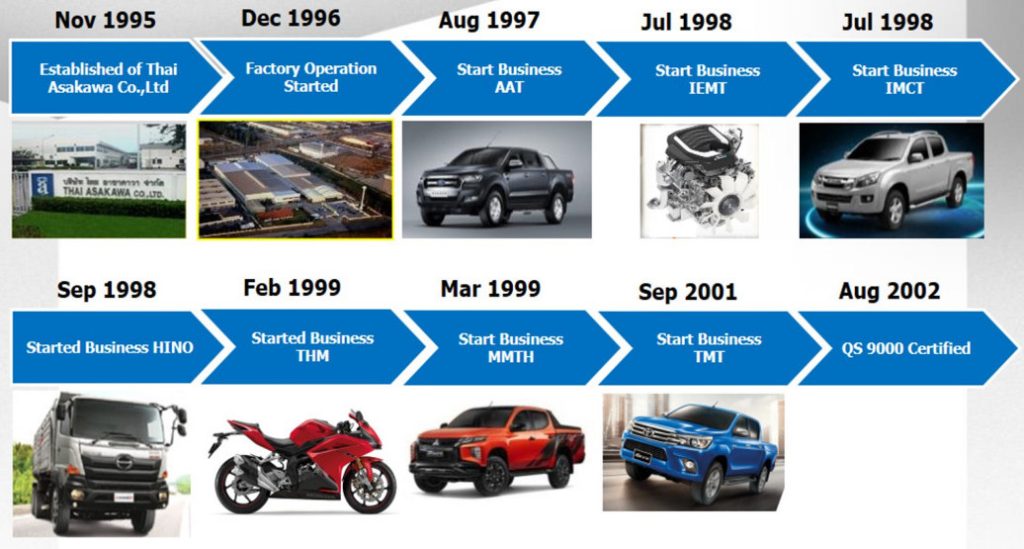

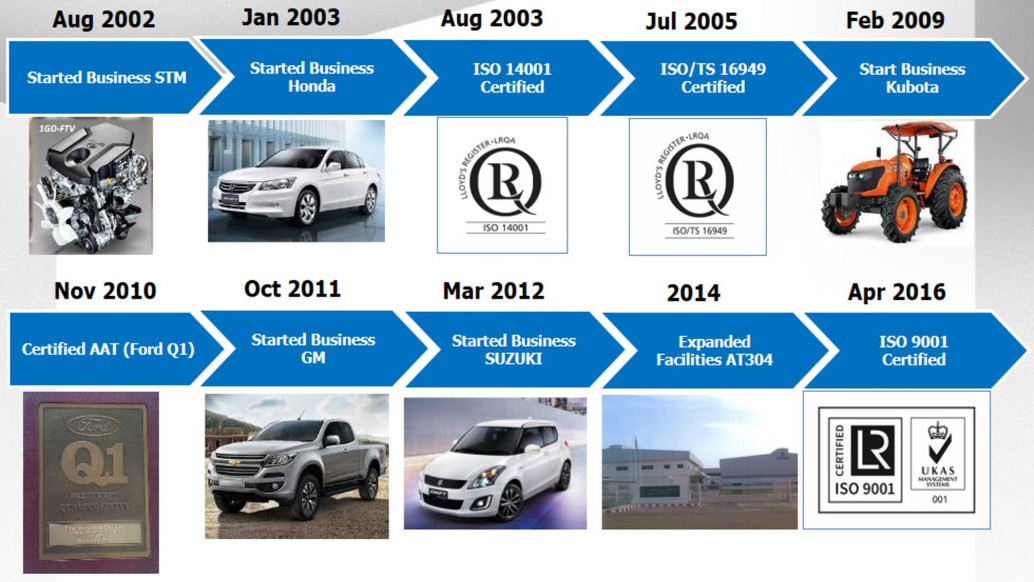

Company History

2003 Expanded facilities(Heat treatment,Forging,Thread rolling,Cutting machine, etc)

Qualified as ISO14001

2004 TOYOTA VIGO started production in Thailand

Expanded facilities(Forging,Thread rolling,Cutting machine, Grinder)

2005 Qualified as TS16949

Expanded facilities(triatomic chromeplating)

2006 Expanded factory and facilities(Heat treatment,Forging)

2009 SIAM KUBOTA started trading

2010 Qualified as AAT(FORD) Q1

2011 GM Thailand/Brasil started trading

2012 SUZUKI MOTOR(THAILAND)CO.LTD started trading

2013 Expanded facilities(Forging,Thread rolling,Cutting machine, Grinder)

2014 Expanded facilities (Forging, Plating) / ASAKAWA(THAILAND) CO.,LTD.

Factory operation startedy

AT equipment (Forging machine, Heat Treatment, carburizing , Geomet)

2015 AT equipment (Grider Machine)

2016 AT equipment (Forging machine)

2017 AT equipment (Forging machine,Cutting Machine)

2019 AT equipment (Grinding machine, Cutting machine, Thread rolling machine) ©Asakawa Ltd.,

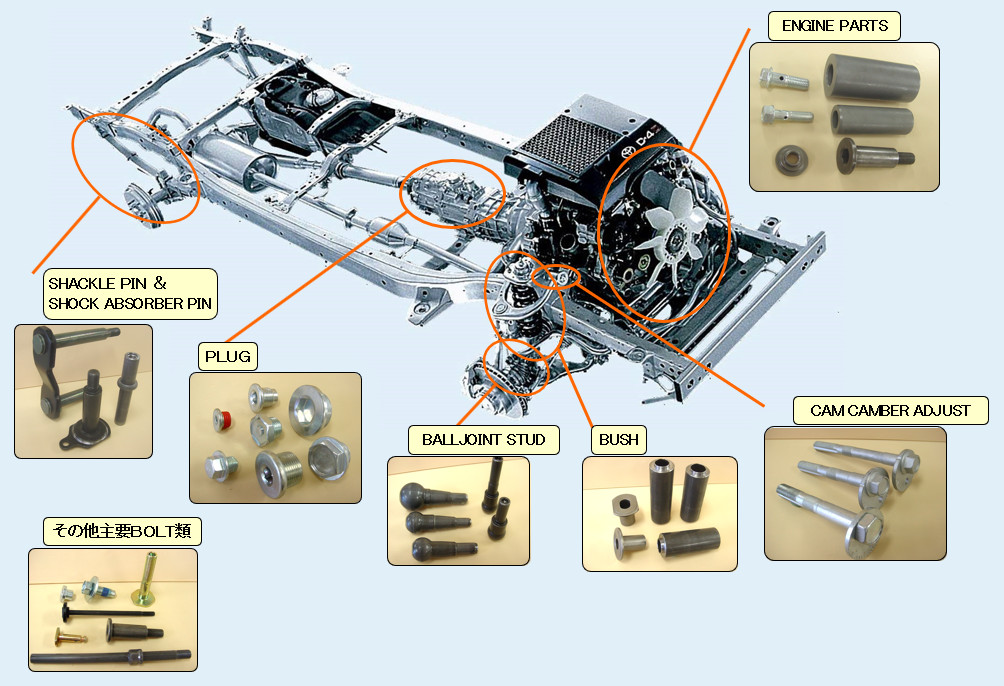

Main Products

Engine Parts

• Bolt; Connecting Rod

• Bolt; Bearing Cap

• Bolt; CyLinder Head

• Bolt; Flywheel

• Retainer Valve Spring

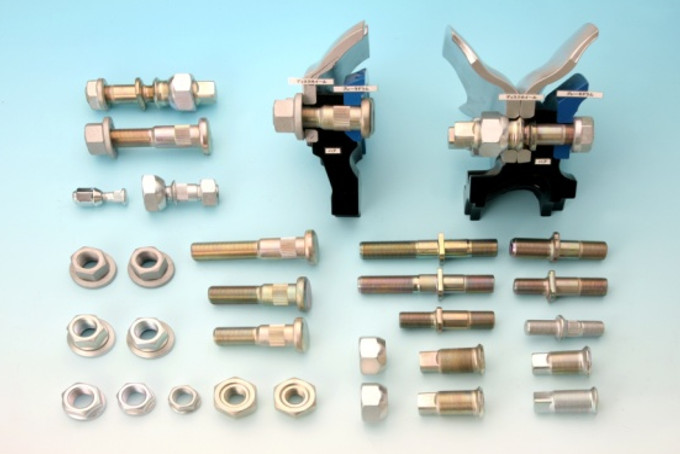

CHassis parts

• Cam Camber

• Bush Bolt

• Hub Bolt

• Hub Nut

general standard parts

• Flange Bolt

• Sems Bolt

• Hexagon Bolt

• Stud Bolt

special parts

• Piston Pin

• Ball Joint

• Ball Rackend

• Shackle Pin Assy

TOYOTA

REVO, FORTUNER

ENGINE PART

STEERING-DRIVE PARTS

ISUZU

New D-MAX, MU-X

ENGINE PART

STEERING-DRIVE PARTS

Machine & Production Process

(1) Cold Forging Machine Total 35 (M6~M35)

(2) Trimming Machine 2 for M16, 1for M20

(3) Press Machine 5 for 60t、2 for 250t、 each 1for 55、75、120、160、200

(4) Thread rolling Machine Automatic 24(M6~M16)、Manual 13(6t、15t)

(5) Grinder Centerless 7, Plane Grinder 4

(6) Cutting Machine 70

(7) Straightening Machine Press type 2, Roller type 2

(8) Heat Treatment 3

(9) Shot blasting 2

(10) Plating 3(Baking furnace, Including triatomic chromeplating facilities)

(11) Inspection sorter Machine 10

(12) Other 15

(13) Inspection Roundness measuring instrument,Microscope, Shape measuring instrument

Zoomscope,Projector, Magnetic Particle machine, Air-Micro meter

Fluorescence X-rays film thickness meter,Salt water mist examination container

Atomic absorption, Pulling testing equipment, HRC hardness-meter, HV hardness-meter.

Calibration and Testing Room